In Summary

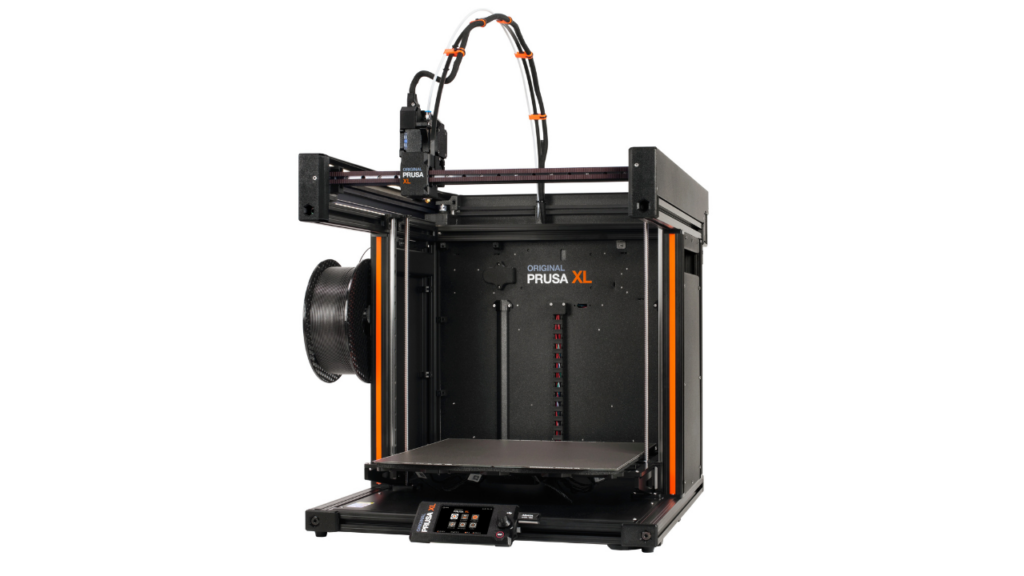

When it comes to 3D printers, the Prusa CORE One stands out as a state-of-the-art machine designed to deliver precision, speed, and reliability. Whether you’re an educator, a professional designer, or a maker, this printer offers the perfect blend of performance and ease of use. Built on a robust CoreXY architecture and enclosed aluminum frame, the CORE One brings high-quality 3D printing within reach for a wide range of users.

Revolutionary CoreXY Technology for Superior Printing

At the heart of the Prusa CORE One lies its CoreXY motion system — an innovative design that significantly improves printing speed and accuracy. Unlike traditional Cartesian printers, CoreXY moves the print head using a belt-driven system that reduces the moving mass. This means the printer can move faster without compromising the quality or detail of your prints.

The reduced inertia also results in smoother and quieter printing, a major plus for classrooms and shared workspaces. Plus, CoreXY architecture handles large or complex prints with ease, providing consistent results every time.

Durable Aluminum Frame for Stability and Precision

Precision in 3D printing requires a stable foundation. The Prusa CORE One features a rigid aluminum frame that minimizes vibrations during the print process. This strong build maintains dimensional accuracy throughout long print sessions, which is especially important for commercial or educational settings where reliability and repeatability are crucial.

An enclosed build chamber keeps the printing environment stable by maintaining consistent temperatures. This reduces warping and other common print failures, especially when working with materials like ABS or nylon. The enclosure also enhances safety by protecting users from high temperatures and moving parts.

Versatile Extruder Supports Wide Range of Filaments

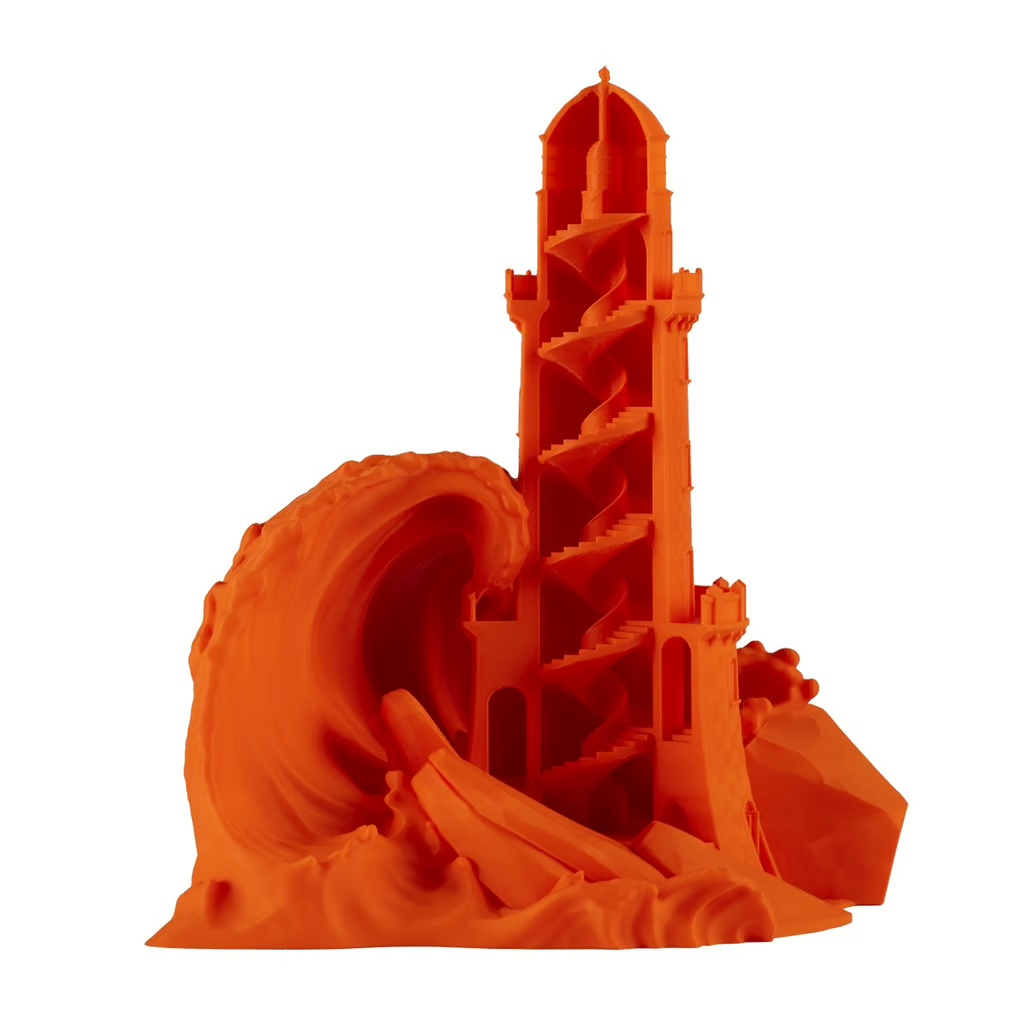

The CORE One is equipped with a direct-drive extruder, which improves filament control and allows printing with a variety of materials. From common filaments such as PLA and ABS to flexible TPU and composite filaments filled with wood, carbon fiber, or metal, this printer supports your creative and functional needs.

This versatility makes the Prusa CORE One an ideal tool for prototyping, education, and small-scale manufacturing. Users can experiment with different materials to create prototypes, functional parts, or intricate models.

Connectivity and User-Friendly Interface

Modern 3D printing demands smart connectivity options. The Prusa CORE One offers Wi-Fi, Ethernet, and USB connections, enabling you to easily send print jobs from your computer or control the printer remotely.

The intuitive touchscreen interface simplifies machine operation, providing real-time status updates and easy access to settings. Whether you’re a beginner or an experienced user, the interface helps streamline your workflow.

Seamless Software Integration

Prusa printers are known for their software ecosystem, and the CORE One is no exception. It works seamlessly with PrusaSlicer, a powerful slicing software that converts 3D models into printing instructions. PrusaSlicer includes presets for various materials and printers, helping users get started quickly and optimize print settings for the best results.

Additionally, Prusa Connect allows users to manage multiple printers remotely, making it easier for schools or businesses to oversee print farms and increase productivity.

Ideal for Education and Professional Use

The Prusa CORE One is designed to meet the demands of educational institutions and professional environments alike. Schools benefit from a safe, reliable machine that helps students learn about 3D printing technology hands-on. Teachers can integrate it into STEM curriculums with confidence, knowing the printer’s stability and user-friendly features support a smooth learning experience.

In commercial settings, designers and engineers gain a dependable tool for rapid prototyping and small-batch production. The ability to print detailed, durable parts fast makes it a valuable asset for product development and testing.

Technical Specifications

| Feature | Description |

|---|---|

| Printing Technology | Fused Filament Fabrication (FFF) |

| Motion System | CoreXY |

| Build Volume | 250 × 210 × 210 mm |

| Frame Material | Aluminum |

| Extruder | Direct-Drive |

| Supported Filaments | PLA, ABS, TPU, Composites |

| Connectivity | Wi-Fi, Ethernet, USB |

| Software Compatibility | PrusaSlicer, Prusa Connect |

Why Invest in the Prusa CORE One?

Choosing the right 3D printer is key to unlocking creativity and productivity. The printer offers a future-proof solution that balances speed, precision, and versatility. Its CoreXY design and sturdy frame make it ideal for detailed, reliable prints, while the wide material compatibility opens doors to countless applications.

Whether you're teaching the next generation of engineers, prototyping innovative products, or running a creative studio, the CORE One delivers professional results without complexity.

For more information and to purchase the Prusa CORE One, visit the official page here: https://www.prusa3d.com/product/prusa-core-one-kit/.