In Summary

The xTool P2S Screen Printing Kit represents a modern step forward in combining laser technology with traditional screen-printing methods. By integrating the powerful xTool P2S CO₂ laser cutter with a specially designed screen-printing kit, it offers creators, educators, and businesses a faster and more precise workflow. In this article, we compare the Xtool Printing Kit with traditional screen-printing setups and other alternatives to highlight its advantages in speed, precision, and usability.

1. Speed and Efficiency

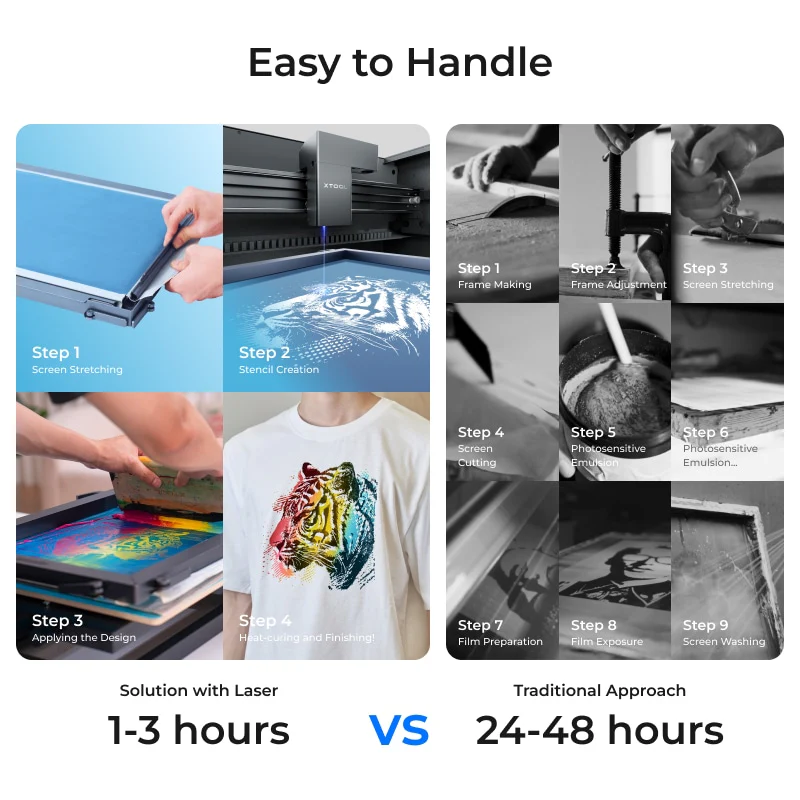

One of the most significant benefits of the Xtool Printing Kit is the time it saves. Traditional screen-printing methods often require a full day or more to prepare a stencil. The manual process involves coating a screen with emulsion, exposing it under UV light, drying, and washing. This is not only time-consuming but also prone to errors.

By contrast, the xTool P2S Printing Kit allows users to create stencils in as little as one hour. With laser precision, the process of preparing designs becomes faster, more reliable, and highly repeatable. The kit also includes an EasyStretch frame system that allows screens to be stretched in under 30 seconds—something that typically takes much longer with manual tools.

2. Precision and Quality

Traditional printing kits rely on manual emulsion techniques that can sometimes result in uneven coating, distorted graphics, or loss of fine details. This can be frustrating for professionals and students alike, especially when working with intricate designs.

The Xtool Printing Kit, on the other hand, uses a laser beam finer than a strand of hair to engrave designs directly onto the stencil. With precision as fine as 0.01 mm, even the most detailed graphics are preserved. The result is a stencil that produces high-quality, distortion-free prints, reducing the chance of wasted materials and failed attempts.

3. Multicolor Printing Advantages

For anyone familiar with screen printing, multi-color overprinting can be one of the biggest challenges. Aligning multiple screens for perfect registration requires patience and experience. Traditional printing kits often lack fine adjustment tools, which can lead to misaligned or blurry results.

The Xtool Printing Kit addresses this issue with a built-in 3-axis micro-registration system, quick-release clamps, and frame-fixing pieces. This setup makes it easier to achieve perfect alignment when layering multiple colors. It saves time, reduces errors, and allows even beginners to experiment with complex multi-color designs.

4. Educational and Creative Benefits

In educational environments, time and clarity are key. Traditional printing methods are valuable for teaching hands-on skills but can be slow and difficult for large groups of students to manage within limited class periods.

The Xtool Printing Kit combines digital design with hands-on printing in a seamless workflow. Students can design digitally, use the laser cutter to prepare stencils, and then print their designs—all in the same session. This encourages experimentation, creativity, and problem-solving while still giving learners the tactile experience of traditional printing.

5. Versatility and Compatibility

The Xtool Printing Kit is designed to work specifically with the xTool P2S laser cutter, offering a smooth integration between cutting and printing. With the addition of accessories like a riser base, users can process larger or thicker materials, extending the creative possibilities.

Compared to traditional printing kits or other add-ons, this integration simplifies the workflow and ensures a consistent level of accuracy. Instead of manually aligning separate tools, the kit takes advantage of the laser’s precision to create a more efficient and reliable system.

6. Real-World Usability

While the Xtool Printing Kit has many advantages, users should also consider the learning curve. Setting up the system and configuring the software may take some trial and error, especially for beginners. However, once mastered, the kit significantly outperforms traditional methods in terms of both quality and speed.

Traditional kits, while slower, do not require advanced equipment and can be more portable. For artisans who value the craft of traditional methods, they may still hold appeal. But for educators, small businesses, and creators seeking efficiency, the xTool solution clearly provides an edge.

7. Summary Comparison Table

| Feature | Xtool P2S Printing Kit | Traditional Printing Kits |

|---|---|---|

| Stencil Preparation Time | ~1 hour (laser-based workflow) | 24 hours or more |

| Frame Setup | EasyStretch, ~30 seconds | Manual stretching |

| Precision | Up to 0.01 mm, laser engraved | Limited, prone to distortion |

| Multi-Color Alignment | 3-axis micro registration system | Manual, less accurate |

| Educational Value | Digital-to-print workflow | Hands-on but slower |

| Ease of Use | Requires some setup learning | Familiar but time-intensive |

Conclusion

The Xtool P2S Printing Kit modernizes screen printing by combining speed, precision, and versatility. Compared to traditional kits, it saves significant time, preserves design details with laser accuracy, and simplifies multicolor printing. Its integration with the P2S laser cutter makes it an especially powerful choice for schools, makerspaces, and creative studios.

While traditional screen printing still has its place for teaching manual skills, the Xtool Printing Kit delivers a more efficient and future-focused solution. For anyone looking to expand creative possibilities while reducing preparation time, this kit is a game-changer.

👉 Learn more here: xTool P2S Screen Printing Kit