In Summary

When it comes to metal fabrication, choosing the right equipment can significantly impact cost, efficiency, and output quality. xTool, a trusted name in the industry, offers two complementary solutions: the xTool Selected Air Compressor & Air Dryer and the xTool MetalFab Laser Welder & CNC Cutter. While one enhances gas efficiency for cutting, the other is a full-fledged laser cutter and welding system. Let’s break down their advantages and disadvantages to help you decide which setup works best for your workshop.

Quick Overview

- xTool Selected Air Compressor & Air Dryer

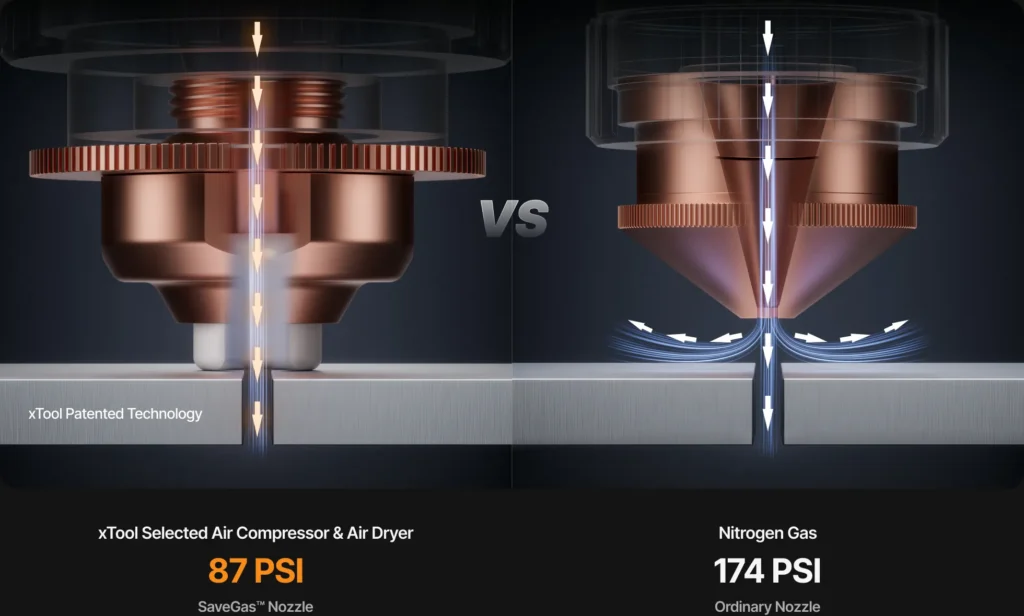

Designed to provide clean, dry, high-pressure air, this system is built specifically for the MetalFab. It allows makers to replace expensive industrial gases with clean compressed air for metal cutting, reducing costs while improving cut quality. - xTool MetalFab Laser Welder & CNC Cutter

A powerful multi-functional machine capable of welding, CNC cutting, and metal cleaning. Available in different power options (800W, 1200W), the MetalFab is one of the most advanced laser cutter systems in the unit lineup, ideal for heavy-duty fabrication.

Key Features at a Glance

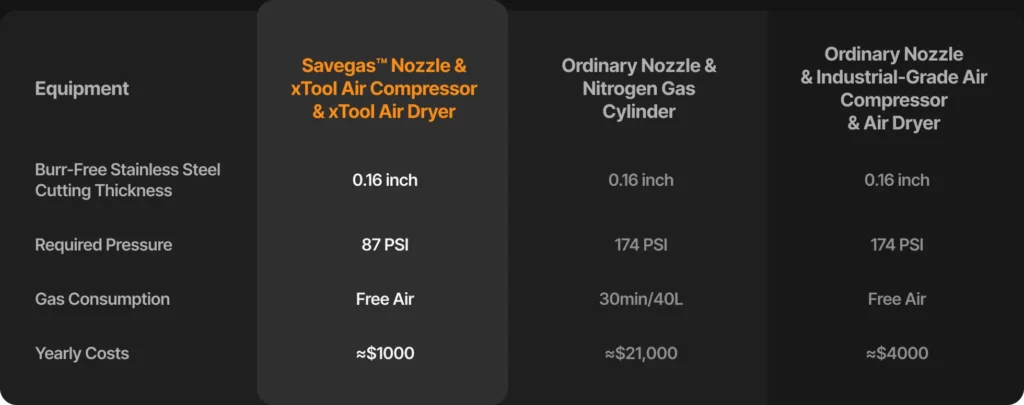

| Feature | xTool Air Compressor & Dryer | xTool MetalFab Laser Welder & CNC Cutter |

|---|---|---|

| Max Pressure & Flow | Up to 145 PSI / ~14.1 CFM | Dependent on configuration (800W / 1200W) |

| Air Quality | Removes ~99.999% oil & rust, ~99.99% moisture | Supports nitrogen, argon, or compressed air cutting |

| Metal Cutting Ability | Enables clean cuts up to 4 mm stainless, 4 mm aluminum, 3 mm brass (with SaveGas™ nozzle) | Cuts up to ~10 mm steel (1200W model), precision ±0.1 mm |

| Functions | Air supply only | Welding, CNC cutting, rust removal |

| Usability | Compact, plug-and-play | Advanced machine with software and camera support |

Advantages

xTool Air Compressor & Dryer

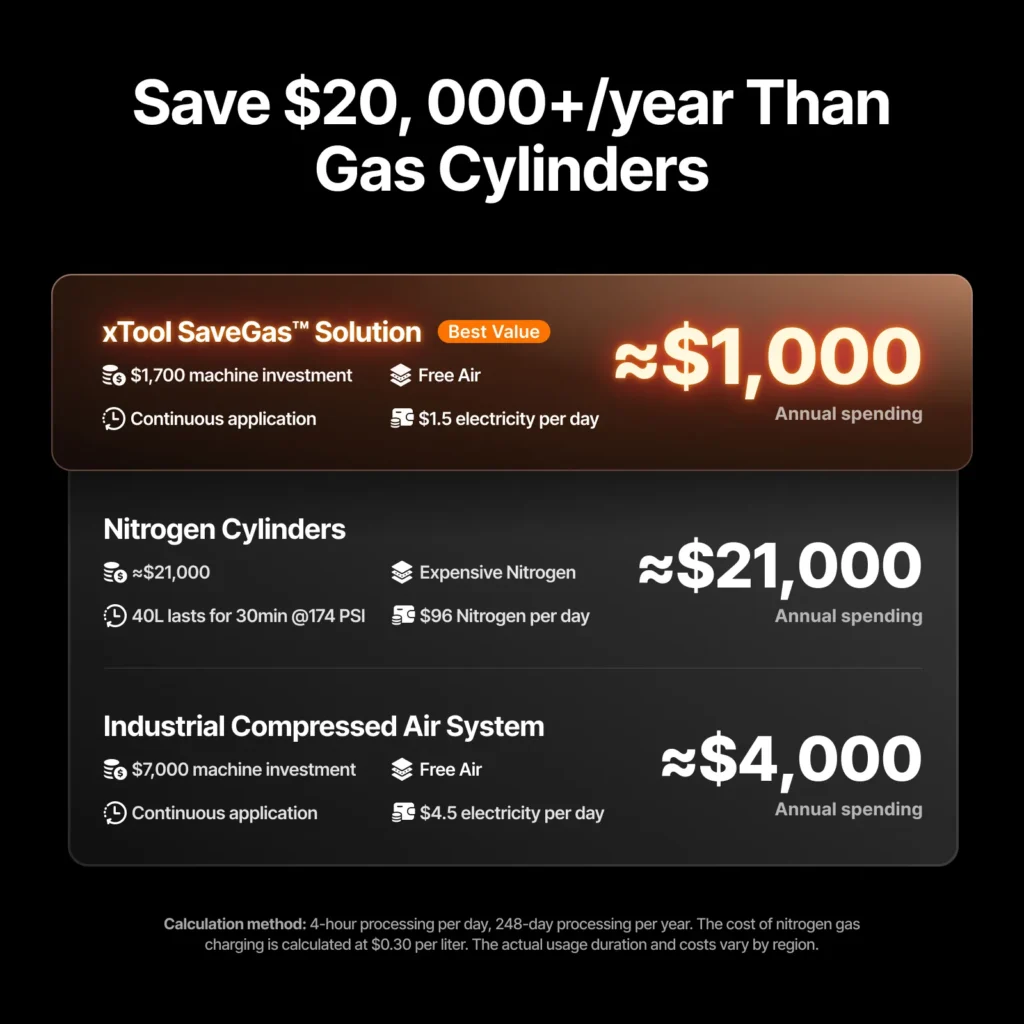

- Cost Savings – Replaces costly industrial gases with clean compressed air, significantly reducing operating costs for frequent cutting tasks.

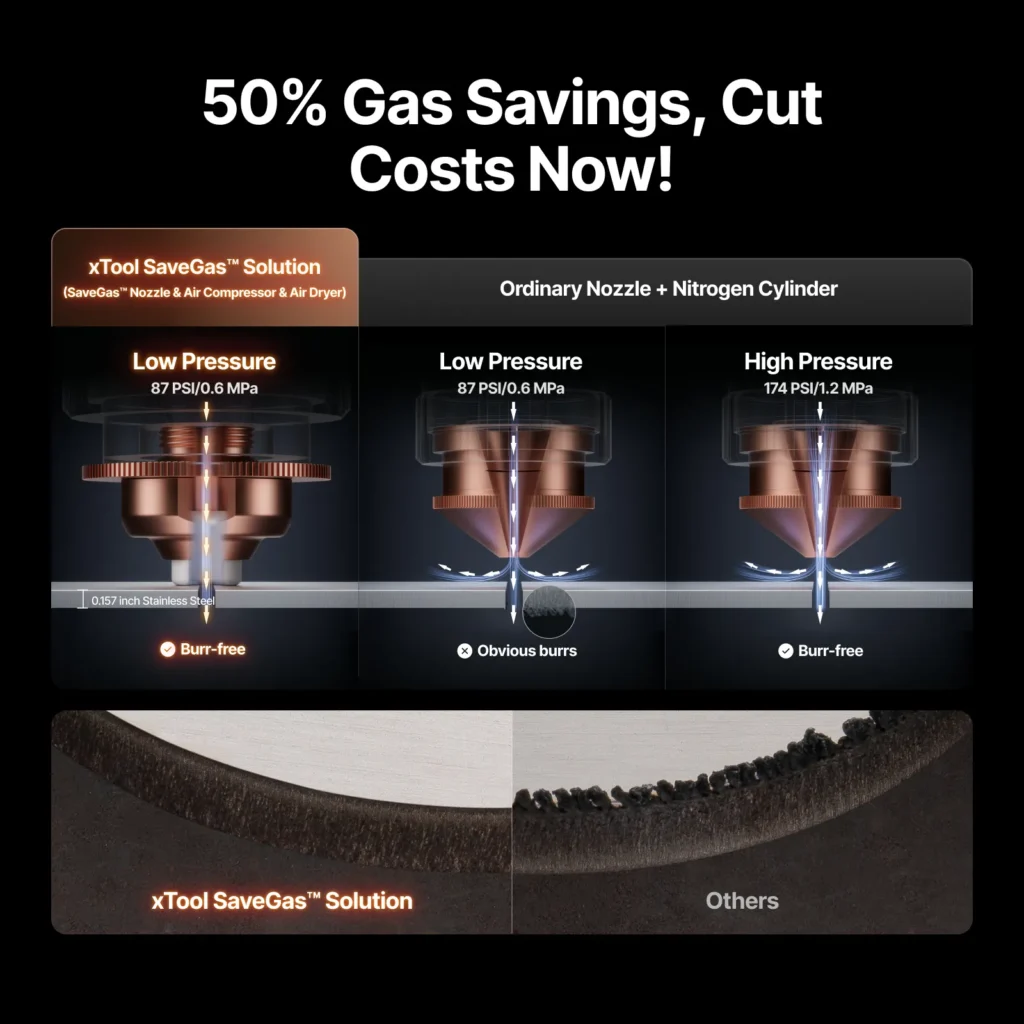

- Improved Cut Quality – Dry, oil-free air prevents oxidation, burrs, and nozzle contamination, resulting in smoother edges.

- Compact and Practical – Easier to install and manage compared to large industrial compressors.

- Durable – Built to perform in a wide range of working environments (−10 °C to +40 °C).

xTool MetalFab Laser Welder & CNC Cutter

- Multi-Function in One Machine – Acts as a high-power laser cutter, welding machine, and cleaning tool.

- High Power Performance – The 1200W version can cut thick metal sheets with high precision, competing with industrial-grade machines.

- Smart Technology – Features like dual cameras, VibeFreeCut™, FlexiTrack™, and ObstacleFree™ help optimize accuracy and workflow.

- User-Friendly Software – Comes with a materials library and automated adjustments, reducing setup time.

- High Efficiency – Compared to traditional TIG welding, the MetalFab can be up to 8× faster, saving valuable production time.

Disadvantages

This model Air Compressor & Dryer

- High Initial Cost – At around $1,698, it’s an investment that makes the most sense for users with regular metal cutting needs.

- Maintenance Required – Filters and components need periodic replacement to maintain performance.

- Not Always Suitable for Surface Finish – Even clean air contains oxygen, which can cause slight oxidation compared to nitrogen cutting.

- Limited Functionality – Works only as a support system; it must be paired with the MetalFab or another compatible laser cutter.

This model MetalFab Laser Welder & CNC Cutter

- Expensive Setup – A powerful industrial-grade machine with a price tag to match, especially with high-power configurations.

- Power & Safety Requirements – Needs stable electricity and strict safety measures, such as laser shielding and fume extraction.

- Learning Curve – While user-friendly, achieving the best results still requires practice and training.

- Consumable Costs – Nozzles, lenses, and gases (if required) add to operating expenses.

- Limitations on Highly Reflective Metals – Certain materials like polished aluminum or copper may need special handling.

Best Use Cases

- Air Compressor & Dryer is ideal if you already own or plan to purchase the MetalFab and want to reduce long-term gas expenses. It enhances cut quality while lowering operating costs.

- MetalFab Laser Welder & CNC Cutter is the go-to solution if you need an all-in-one system for metal fabrication, from welding to laser cutting. It’s a professional-grade machine built for businesses that demand speed, versatility, and precision.

Together, they form a powerful ecosystem: the compressor ensures cost-effective, clean air supply, while the MetalFab provides industrial-level laser cutting and welding capabilities.

Final Thoughts

If you’re searching for an the unit laser cutter that handles metal with precision and efficiency, the MetalFab Laser Welder & CNC Cutter is the flagship option. For businesses looking to reduce operating costs, pairing it with the Air Compressor & Dryer is a smart long-term investment.

By combining both, you unlock maximum performance, lower costs, and higher-quality results in your metal fabrication projects.

🔗 Official Product Links: